CarEdge saved me over 4,500 dollars on a brand new Honda Pilot. I can't say thank you enough.

Price intelligence

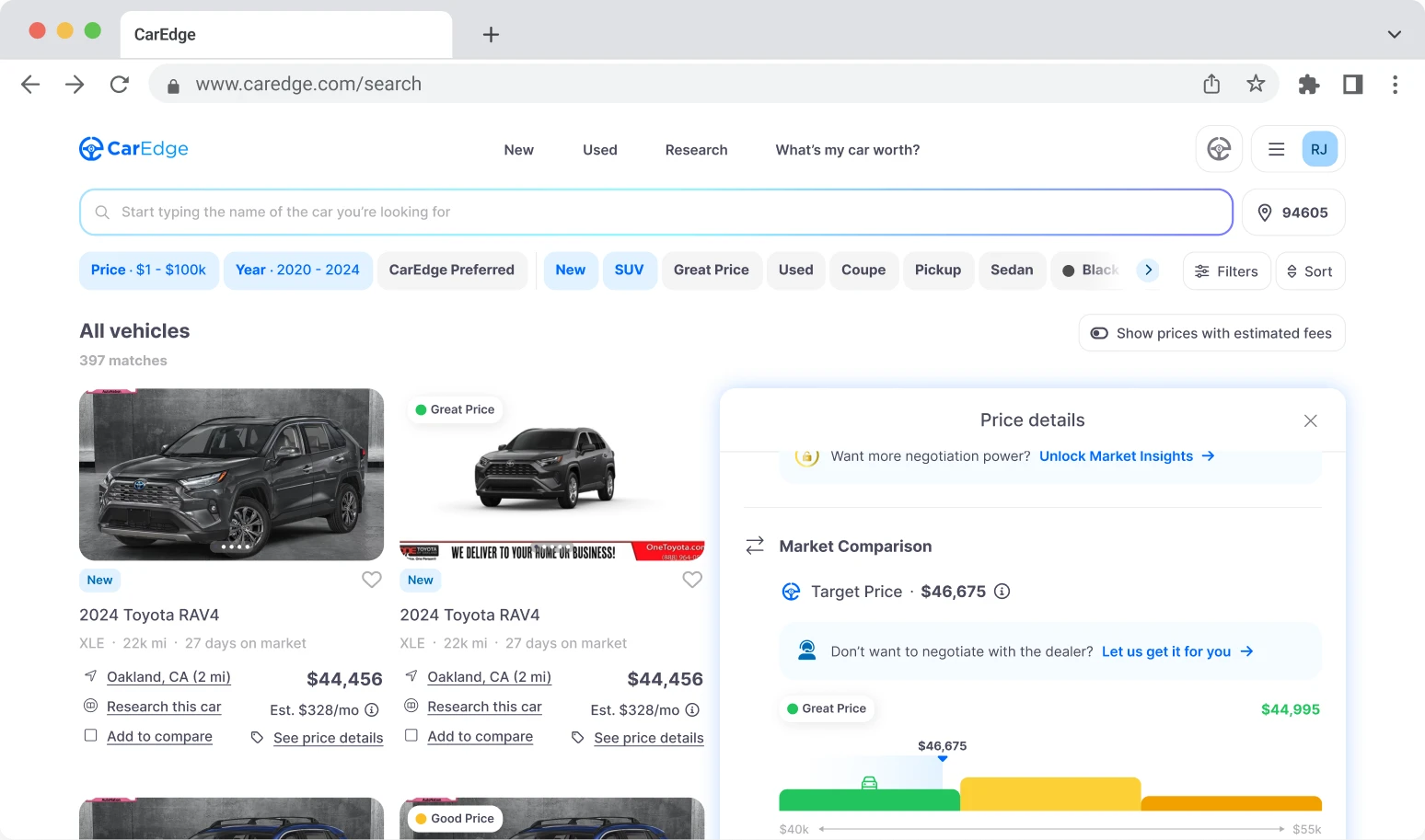

Find a wide range of vehicle listings with market insights on new and used listings near you.

Help us personalize your CarEdge experience — it only takes a second.

Your answers help us personalize your CarEdge journey — we’ll follow up with tips and next steps that match your buying timeline.

As electric cars continue to enter the mainstream, the tug-of-war between EV startups and legacy giants is intensifying. With federal EV tax credits now expired, how will EV sales trend? Will Tesla hold its lead, or will Ford, General Motors and the rest catch up? Bookmark this page for the latest quarterly and monthly sales and market share updates for electric vehicles in the United States.

Q3 2025 EV sales numbers reflect the rush to get ahead of the federal tax credit expiration on September 30, 2025:

In the third quarter of 2025, battery electric vehicle market share reached 10.5% of all new car sales in the United States. This is down slightly from 8.9% one year prior, and nearly unchanged from 7.2% of the market in Q2 2025.

Here’s how U.S. EV sales totals in Q3 2025 compare to the past three years:

| Automaker | Q1 2022 | Q2 2022 | Q3 2022 | Q4 2022 | Q1 2023 | Q2 2023 | Q3 2023 | Q4 2023 | Q1 2024 | Q2 2024 | Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | Q3 2025 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tesla (estimate) | 129,743 | 130,047 | 114,000 | 131,574 | 161,630 | 175,262 | 156,621 | 161,375 | 140,187 | 164,264 | 166,923 | 154,900 | 128,100 | 143,535 | 179,525 |

| Ford Motor Company | 6,734 | 15,273 | 18,257 | 20,339 | 10,866 | 14,843 | 20,962 | 25,937 | 20,223 | 23,957 | 23,509 | 30,176 | 22,550 | 16,438 | 30,612 |

| General Motors | 457 | 7,217 | 15,156 | 16,150 | 20,670 | 15,652 | 20,057 | 19,469 | 16,169 | 21,930 | 32,095 | 43,982 | 31,887 | 46,280 | 66,501 |

| Honda Motor Co | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1,873 | 15,291 | 18,838 | 14,374 | 12,278 | 22,236 |

| Nissan | 4,371 | 3,251 | 1,276 | 3,308 | 5,214 | 4,215 | 6,074 | 5,113 | 5,284 | 7,128 | 10,066 | 8,546 | 6,471 | 9,073 | 3,934 |

| Volkswagen Group | 7,932 | 8,961 | 11,893 | 15,193 | 15,723 | 13,977 | 20,295 | 20,403 | 13,806 | 11,904 | 11,900 | 9,755 | 19,827 | 11,043 | 37,400 |

| Hyundai Group (incl. Kia) | 15,480 | 17,979 | 9,796 | 9,641 | 14,346 | 21,696 | 30,757 | 25,447 | 22,936 | 37,044 | 29,609 | 39,649 | 22,995 | 21,493 | 48,650 |

| Subaru | 0 | 0 | 0 | 919 | 1,359 | 1,613 | 2,791 | 3,109 | 1,147 | 4,238 | 3,752 | 3,310 | 3,131 | 3,370 | 3,471 |

| Toyota Motor N.A. | 0 | 0 | 240 | 985 | 1,840 | 2,893 | 4,221 | 5,718 | 3,500 | 11,607 | 6,851 | 6,309 | 7,064 | 5,964 | 5,032 |

| Mercedes-Benz | 2,091 | 1,959 | 2,717 | 5,656 | 5,053 | 9,029 | 10,423 | 10,767 | 12,250 | 9,270 | 9,447 | 3,763 | 3,472 | 4,611 | 5,973 |

| Mazda | 0 | 0 | 0 | 324 | 15 | 51 | 34 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| BMW Group | 1,171 | 1,082 | 4,337 | 7,099 | 6,585 | 11,990 | 13,594 | 15,364 | 11,455 | 14,081 | 13,028 | 13,876 | 14,234 | 11,094 | 10,950 |

| Jaguar | 0 | 114 | 0 | 298 | 8 | 80 | 86 | 78 | 256 | 1,188 | 779 | 763 | 381 | N/A | N/A |

| Stellantis | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 204 | 235 | 531 | 4,990 | 2,352 | 6,939 |

| Volvo-Polestar | 3,092 | 4,518 | 3,510 | 5,616 | 5,228 | 7,608 | 7,797 | 6,531 | 3,279 | 2,285 | 3,913 | 3,028 | 2,718 | 2,898 | 3,058 |

| Rivian | 1,227 | 4,467 | 6,584 | 8,054 | 7,946 | 12,640 | 15,564 | 13,553 | 13,588 | 13,790 | 10,018 | 8,503 | 8,640 | 10,599 | 13,201 |

| Lucid | 460 | 482 | 1,398 | 1,060 | 1,368 | 1,659 | 1,618 | 1,512 | 1,967 | 1,855 | 2,781 | 3,099 | 2,400 | 2,635 | 4,078 |

| Vinfast | - | - | - | - | 110 | 740 | 1,159 | 1,120 | 927 | 1,225 | N/A | 1,800 | 525 | N/A | N/A |

| Additional EV Models | - | - | - | - | - | - | - | - | - | - | - | - | 5,930 | 3,508 | 2,288 |

| TOTAL US EV sales | 173,561 | 196,788 | 188,924 | 226,789 | 258,882 | 295,355 | 313,086 | 317,168 | 268,909 | 330,463 | 346,309 | 348,879 | 296,227 | 310,839 | 437,487 |

Data source: Cox Automotive

Data for Q3 2025 will be available as automaker sales totals are finalized in October.

| Automaker | Q1 2022 | Q2 2022 | Q3 2022 | Q4 2022 | Q1 2023 | Q2 2023 | Q3 2023 | Q4 2023 | Q1 2024 | Q2 2024 | Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | Q3 2025 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tesla | 74.8 | 66.1 | 60.3 | 58.0 | 62.4 | 59.3 | 50.0 | 50.9 | 52.1 | 49.7 | 48.2 | 44.4 | 43.5 | 46.2 | 40.9 |

| Ford | 4.4 | 7.8 | 9.7 | 9.0 | 4.2 | 5.0 | 6.7 | 8.2 | 7.5 | 7.2 | 8.6 | 8.7 | 7.7 | 5.3 | 7.0 |

| General Motors | 0.3 | 3.7 | 8.0 | 7.2 | 8.0 | 5.3 | 6.1 | 6.1 | 6.0 | 6.6 | 9.3 | 12.6 | 10.8 | 14.9 | 15.2 |

| Honda Motor Co | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.5 | 4.4 | 5.4 | 4.8 | 4.0 | 5.1 |

| Nissan | 2.5 | 1.7 | 0.7 | 1.5 | 2.0 | 1.4 | 1.9 | 1.6 | 2.0 | 2.2 | 2.9 | 2.5 | 2.2 | 2.9 | 1.0 |

| Volkswagen Group | 4.6 | 4.6 | 6.3 | 6.7 | 6.1 | 4.8 | 6.5 | 6.4 | 5.1 | 3.6 | 3.4 | 2.8 | 6.7 | 3.6 | 8.5 |

| Hyundai Motor Group (incl. Kia) | 8.9 | 9.1 | 5.2 | 4.3 | 5.6 | 7.3 | 9.9 | 8.0 | 8.5 | 11.2 | 6.8 | 11.4 | 7.8 | 6.9 | 11.1 |

| Mercedes-Benz | 1.2 | 1.0 | 1.4 | 2.5 | 2.0 | 3.1 | 3.3 | 3.4 | 4.6 | 2.8 | 2.7 | 1.2 | 1.2 | 1.5 | 1.4 |

| Mazda | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Toyota Motor N.A. | 0.0 | 0.0 | 0.0 | 0.4 | 0.7 | 1.0 | 1.3 | 1.8 | 1.3 | 3.5 | 2.0 | 1.8 | 2.4 | 1.9 | 1.1 |

| Subaru | 0.0 | 0.0 | 0.0 | 0.4 | 0.5 | 0.5 | 0.9 | 1.0 | 0.4 | 1.3 | 1.1 | 1.0 | 1.1 | 1.1 | 0.8 |

| BMW | 0.7 | 0.5 | 2.3 | 3.1 | 2.5 | 3.9 | 4.2 | 4.8 | 4.3 | 4.3 | 3.8 | 4.0 | 4.8 | 3.6 | 2.5 |

| Stellantis | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 | 1.7 | 0.8 | 1.6 |

| Jaguar | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.4 | 0.2 | 0.2 | 0.1 | 0.0 | 0.0 |

| Rivian | 0.7 | 2.3 | 3.5 | 3.1 | 3.1 | 4.3 | 5.0 | 4.3 | 5.1 | 4.2 | 2.9 | 2.4 | 2.9 | 3.4 | 3.0 |

| Lucid | 0.3 | 0.2 | 0.7 | 0.5 | 0.5 | 0.6 | 0.5 | 0.5 | 0.7 | 0.6 | 0.8 | 0.9 | 0.8 | 0.8 | 0.9 |

| Vinfast | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.3 | 0.4 | 0.4 | 0.3 | 0.3 | 0.0 | 0.5 | 0.1 | 0.1 | 0.0 |

| Volvo/Polestar | 1.9 | 2.3 | 1.9 | 1.6 | 2.0 | 2.6 | 2.5 | 2.1 | 1.2 | 0.7 | 1.1 | 0.9 | 1.0 | 0.9 | 0.7 |

| Other EV Sales | - | - | - | - | - | - | - | - | - | - | - | - | 2.0 | 2.0 | 0.5 |

Data source: Cox Automotive

In Q3 2025, Tesla was down to 41% of EV market share in America. Tesla remains the dominant player in an increasingly crowded field, even with falling market share. According to analyses by Cox Automotive, Tesla sales accounted for 49% of all EVs sold in the US in 2024, down from 55% in 2023, and 62% in 2022. At the start of 2022, Tesla had a 75% EV market share in America.

Ford, GM, and Hyundai Motor Group continue to fight for second place. Hyundai and Kia EV sales soared in 2024, but have waned this year. Last year, Ford’s EV sales were overtaken by GM somewhat unexpectedly. GM is now running away from Ford, outselling their chief rival nearly three to one.

| Q1 2023 | Q2 2023 | Q3 2023 | Q4 2023 | Q1 2024 | Q2 2024 | Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | |

| Battery Electric Vehicles (BEV) | 7.3% | 7.2% | 7.9% | 8.1% | 7.3% | 8.0% | 8.9% | 8.7% | 7.5% | 7.4% |

| Electrified (HEV, PHEV, BEV) | 14.5% | 16.0% | 17.7% | 16.0% | 17.8% | 19.1% | 21.2% | 30.7% | TBD | TBD |

In 2024, the US EV market share reached 8.1% of all light vehicle sales, up from 7.3% of sales in 2023. In 2022, 5.8% of the new cars Americans bought were fully electric, which was a sharp increase from 3.2% in 2021.

According to EIA.gov, Combined sales of hybrid vehicles, plug-in hybrids, and battery electric vehicles in the United States rose to 16.3% of total new light-duty vehicle sales in 2023. In 2022, hybrid, plug-in hybrid, and BEV sales were 12.9% of total sales.

Electrified powertrains continue to see rapid growth, despite less growth in the electric-only segment.

General Motors President Mark Reuss told CNBC Monday that ‘electrified’ and fully-electric Chevrolet Corvette versions will be out as soon as 2023. An electric Corvette has long been rumored, but this is the first official news about the Corvette EV. 2022 and especially 2023 are shaping up to be pivotal years for GM’s electrification strategy, as the automaker looks beyond the Chevy Bolt towards mainstream EVs like the Silverado EV and Chevrolet Equinox EV.

First, GM will debut an electrified Corvette in 2023. This will be either a hybrid Corvette, a plug-in hybrid, or both. News of a hybrid Corvette may perplex Corvette aficionados, however other performance cars have seen much success with hybrid powertrains, including the BMW i8 and the new McLaren Artura.

To those accustomed to associating General Motor’s electric vehicles with appliance-looking Chevy Bolts, fear not. The new electric Corvette will be powered by the all-new Ultium battery and electric motor platform. The Ultium platform recently made its production debut in the Cadillac Lyriq luxury crossover, as well as the lavish GMC Hummer EV. GM partnered with LG Chem to engineer the Ultium battery. LG Chem also makes batteries for Tesla, Lucid, Stellantis, and other automakers.

The strengths of the Ultium platform are lowered battery costs, higher energy efficiency, and faster charging. All three of these improvements are going to be central to GM’s fight to compete with both Tesla and Ford in the years to come.

General Motors CEO Mary Barra says that the new Ultium electric platform will unlock battery production at scale for less than $100 per kilowatt-hour. Combined with Ultium’s improved efficiency and ultra-fast charging (at up to 350 kW speeds), GM is banking on their new platform to catch up to Tesla. In fact, the Ultium battery and motor powertrain was chosen by Honda’s engineers to power the upcoming Honda Prologue electric SUV.

For now, General Motors President Mark Reuss is not sharing many details. He did liken the announcement of the Corvette EV to the coming 2023 Corvette Z06, so he’s setting the bar high. Chevrolet shared a 30-second teaser video, and all-wheel drive looks likely. That would put the Corvette EV on par with competing electric sports cars, including Teslas. We’ll be sure to update this page with the latest once more details are announced.

What do you think about the electric Corvette? Join the CarEdge Community to connect with auto enthusiasts and car buying experts. We’ve helped members save thousands of dollars in today’s hectic market. Join the fastest-growing automotive community online at CarEdge to see why car ownership minus the headaches is changing the game.

If you’re in the market for an affordable electric vehicle, you’ve likely already arrived at the realization that ‘affordable’ doesn’t mean cheap in 2022. In fact, our own CarEdge list of the best affordable electric cars features one car (the Tesla Model 3) that now starts just shy of $50,000. Are there any truly cheap electric cars available today? You may be surprised with what we found.

After earlier rumors suggested that the Nissan LEAF was to be discontinued, a Nissan executive recently stated that the LEAF is here to stay. That’s GREAT news for EV affordability.

We must point out that General Motors decided to slash the price of the LEAF’s competitor, the Chevy Bolt, to steal the title of ‘cheapest EV in America.’ More on that below.

Price: Starting at $27,400

Range: 150 to 226 miles, depending on battery size

Charging Speed: Either 50 kW or 100 kW speeds, depending on battery

Tax credit: It qualifies!

Available at dealers now: See who has inventory at CarEdge Car Search: Nissan Leaf

Tesla is the face of electric cars today, but for years it was the Nissan Leaf at center stage. When Nissan brought the Leaf to market in 2010, it was a short-ranged novelty that somehow began to catch on. With just 73 miles of range on a good day, the first iteration of the Leaf was a bug-eyed appliance good for around town, but not much else.

Over a decade later, and the 2022 Nissan Leaf is a lot better than the first. However, it’s still a budget vehicle, and you get what you pay for. Still, it’s a great entry point into EVs for many. The Leaf now has enough range to make regional travel realistic, but charging speeds have unfortunately remained too slow to make it easy. If you’re eager to get into an electric car for under $30,000, you’ll surely want to check out the 2022 Nissan Leaf.

Price: Starting at $26,595

Range: 259 miles

Charging Speed: 55 kW speeds (adds 100 miles in 30 minutes of charging)

Tax Credit: The Bolt no longer qualifies for the federal EV tax credit, but state incentives may apply

The 2023 Chevy Bolt is the cheapest electric car today. It is available at dealers nationwide, as long as the mandatory recall fixes have been completed. See who has inventory at CarEdge Car Search: Chevrolet Bolt and Bolt EUV

General Motors has sold over 100,000 Chevrolet Bolt EVs since launching the subcompact crossover in 2016. In 2021, the Bolt gained a new sibling: the larger Bolt EUV. Shortly after the Bolt EUV joined the show, several Bolt battery fires spurred a very urgent recall into action. When all was said and done, battery supplier LG Chem was found to be responsible for the Bolt battery fires, and agreed to pay General Motors $2 billion in damages.

Fast forward to 2022, and most Chevrolet Bolt’s (all for sale) have received new battery packs. The Bolt is a GREAT deal now that it’s fixed. If you’re never in a rush on road trips (or just plan to use the car around town), the 2022 Chevrolet Bolt is worth a look. It charges painfully slow, but hey, it is the cheapest electric car today.

If you check out used Bolts, request official documentation showing that all recall work was completed. The Bolt will be eligible for the new EV tax credit here in the United States, but only after 1/1/2023. See our full guide to EV tax credits for more info.

Price: Starting at $34,000

Range: 258 miles

Charging Speed: 100 kW speeds (180 miles added in 47 minutes)

Tax Credit: It qualifies!

Available at dealers nationwide. See who has inventory at CarEdge Car Search: Hyundai Kona EV

The 2022 Hyundai Kona EV is no Tesla, but it has decent range and room to fit most lifestyles. Plus, it’s really cheap AND still qualifies for the $7,500 federal tax credit.

For just $34,000 before incentives, you can become the owner of the original Hyundai EV. This front-wheel drive subcompact crossover gets 258 miles on the charge, exceptional range for a budget EV. Some owners get over 275 miles on a single charge. The Limited trim, top-of-the-line option comes in at $42,500.

If you plug in at home, charging to 100% from a 240-volt dryer outlet will only take you about 9 hours from 10% state of charge. That will get you a full battery overnight while you’re sleeping. At a fast charger, the Kona is behind the competition. In 47 minutes, the Kona Electric charges from 10% to 80% capacity.

The all-new Hyundai IONIQ 5 has stolen the show with more range, MUCH faster charging, and retro looks, but it starts closer to $45,000 with destination and availability is very limited. For those who are willing to give up a few luxuries, the Hyundai Kona EV is a solid choice.

Price: Starting at $39,990

Range: 239 miles

Charging Speed: 100 kW at a DC fast charger (adds 100 miles of range in about 30 minutes)

Tax Credit: It qualifies!

Available at dealers nationwide. See who has inventory at CarEdge Car Search: Kia Niro EV

The Kia Niro electric version is the sibling to the aforementioned Hyundai Kona EV. Both source their power from a 64 kilowatt-hour battery, which is a tad smaller than more expensive electric cars. The Niro EV can charge at up to 100 kilowatt speeds at a fast charger. At least that’s better than the Nissan LEAF and Chevy Bolt.

The Niro EV’s back seat is slightly more spacious than the Kona’s, so it’s more popular with families and those with large pets. There’s also a plug-in hybrid version. For just a few thousand dollars more, keep in mind that you could check out the base trims of the newer Kia EV6, Hyundai IONIQ 5 and Volkswagen ID.4.

Price: $30,750

Range: 114 miles

Charging Speed: 50 kW speeds (about 90 miles of range in 36 minutes)

Tax Credit: It qualifies!

Available at select dealers nationwide. See who has inventory at CarEdge Car Search: MINI Cooper Electric

For just over $30,000, you can own an electric Mini. It’s practically a luxury golf cart! Jokes aside, it’s not a bad deal IF you don’t plan to go very far. With 114 miles of EPA-rated range, it’s a zippy way to scoot around town.

Price: $34,695

Range: 100 miles

Available in California to those who don’t travel much. Check it out if you must at CarEdge Car Search: Mazda MX-30

Why didn’t I include Mazda’s first fully-electric vehicle on this list? It’s a brand-new model, yet it only gets 100 miles of range on a charge. That, and the fact that it is only sold in California as a regulatory compliance vehicle for now. Come on, Mazda! That’s not enough range to safely make it across Los Angeles!

An electric car under $35,000? Sounds like science fiction, but as you can see, a few can be had for what used to be considered average car prices. Most of these cheap electric cars don’t have the best range, the fastest charging or the need for speed, but they won’t drain the bank like a Tesla will. Let me know which cheap EVs you’re checking out in 2022.

Some parting advice: consider all options, and test drive as many electric vehicles as you can. You’ll be amazed at what’s out there, and even more amazed at what’s to come.

Electric trucks are few and far between on highways, but they’re all the rage online. There are fewer than 3,000 electric trucks on the road today, but at least 1.5 million reservations are in the books for upcoming electric truck models. Will trucks ever catch up to crossovers in the electrification of the auto industry? With how many models are in the development pipeline, it will be interesting to find out. Let’s take a look at every electric truck on the way, and the few you might catch a glimpse of in 2022.

Introduced: Late 2021

Range: 314 miles

Fuel economy: 71 MPGe

Cost to charge 0 – 100% at home: $19

Price: $78,975 – $121,690

“It’s bigger than a Ford Ranger, smaller than a F-150, and a whole lot more expensive.”

The 2022 Rivian R1T is the most common electric truck on the road today, but that doesn’t mean it will be easy to find one. About 2,000 have been sold as of spring 2022. As is often the case, supply shortages (and inflation) have put a damper on the much-anticipated rollout of Rivian’s first model.

Nevertheless, it’s a very capable truck. The R1T can tow more than 11,000 pounds and the pickup offers a payload capacity of 1760 pounds. And it’s fast, with a 0-60 time of 3.3 seconds. It’s a rugged, outdoorsy-themed truck for those who use their pickup for more play than work. If you’re in the market for one, get in line. If you’re lucky (and have a deep wallet), you just might take delivery of one by the end of 2023. Rivian prices recently jumped by $10,000 – $20,000, so don’t expect a Rivian for the original price of $69,000.

Introduced: Late 2021

Range: 329 miles

Fuel economy: 47 MPGe

Cost to charge 0 – 100% at home: $30

Price: $80,000 – $110,000+

“American excess at its finest….. and least efficient.”

If you would like a 9,000-pound, crab-walking mammoth of a truck that can seemingly overcome physics to reach 60 miles per hour in three seconds, General Motors has you covered. The revived Hummer is a large luxury truck meant to turn heads more than it’s meant to haul stuff to the worksite.

The Hummer EV’s #1 party trick is the crab-walk. That’s when the truck turns using all four weeks, allowing it to slide through traffic. The EPA-rated range of 329 miles is a bit misleading. It has a MASSIVE 212 kilowatt-hour battery. That’s triple the capacity of most electric crossovers! While technically it starts around $80,000, used ones are already selling for a quarter of a million dollars.

Introduced: Late 2022

Range: 230 – 300 miles

Fuel economy: 68 MPGe

Cost to charge 0 – 100% at home: $14 – $20

Price: $39,974 – $90,874

“This will be the first mass-produced electric truck on the market, but we’re bracing for the dealer markups.”

We recently detailed all we know about the upcoming electric F-150 in a special CarEdge preview. It turns out that truck fans are REALLY looking forward to the Lightning. The question remains, can Ford make enough of them?

Here’s What Stands Out With the F-150 Lightning:

Ford has 200,000 reservations in the books for the F-150 Lightning, so new orders can expect a 2024 delivery. If you’re patient, this just might be worth the wait.

Here’s everything we know about the Ford F-150 Lightning.

Introduced: Spring 2023

Range: Up to 400 miles (depending on battery size/trim)

Cost to charge 0 – 100% at home: $28

Price: $39,900 – $80,000+

“It’s the direct competitor to the F-150 Lightning, but it will charge a LOT faster.”

When Ford made such a big deal with the unveiling of the F-150 Lightning, we all knew General Motors would be cooking up something special. The Chevrolet Silverado EV was unveiled at last, and the specs and looks have exceeded expectations. Chevy claims it has faster charging, more power, and more range than the Ford.

It’s a flexible truck too, and one that’s definitely going to see some worksite use. The storage capacity of the 5-foot-11-inch bed can be extended to 9 feet with the ’available’ Multi-Flex Midgate.

GM says that the new Silverado is basically a rolling generator, if you buy the required accessories. “When combined with the available accessory power bar, the Silverado EV’s PowerBase charging system offers up to 10 outlets, to provide a total of 10.2kW of all-electric power for countless worksite or recreational needs, including powering your home, with the required equipment.” It can even charge other electric vehicles!

Learn more about the Chevrolet Silverado EV in our in-depth analysis.

Introduced: 2023

Range: Up to 400 miles

Price: Unavailable

“Did someone make a truck in Minecraft?!”

Ever since Tesla pulled the curtains back in November 2019, the world has divided into two camps: those who adore the Cybertruck’s angular, Mars-ready looks, and those who abhor it. No matter what your opinion is, it’s still just an idea for now. Tesla has repeatedly pushed back its arrival, and now says that 2023 will be the start of production.

The Cybertruck will have 3,500 pounds of payload capacity, and can tow 14,000 pounds. Those specs are on another level for sure. It’s also a performance-oriented truck, with a 0-60 time of 2.9 seconds. Pricing had previously been announced to start at $40,000 for rear-wheel drive base variants, but that was later removed from the Tesla website. We expect pricing to range from $55,000 to over $80,000, but it’s pure speculation at this point.

In late 2021, Toyota teased the above image of an electric truck. It closely resembles an electric Tacoma, which would be a dream come true for many Toyota fans. They haven’t said a word since, but we’ll update you with the latest once we know more.

Stellantis has taken its sweet time getting into EVs. In 2024, the Ram 1500 electric truck will make a debut with a range of up to 500 miles and futuristic design cues. It will be capable of fast-charging, a quick 0-60 time, andthe latest tech from Stellantis.

The electric Ram 1500 will be built on the new STLA platform that is currently in development. More to come.

They say it’s coming, but we don’t know much yet. The electric Sierra will share the same powertrain engineering as the Silverado EV.

“Like the GMC Hummer EV, the electric Sierra will be purposefully built on the Ultium Platform with the premium materials and capability customers have come to expect from GMC trucks,” says GMC.

The Canoo ‘Pickup Truck’ has more in common with the Tesla Cybertruck that one might suspect. It’s weird-looking, has space-age ambitions, and has been repeatedly delayed. Canoo has undergone multiple leadership shakeups, and that has delayed the launch of Canoo’s first products by a few years (and counting).

The Canoo truck has a targeted payload capacity of 1,800 pounds, a 6’ 8” bed when extended, and about 500 horsepower. At least 200 miles of range are to be expected on a charge. Hopefully it turns out to be at least 250 miles considering the competition.

As odd and mysterious as the Canoo Pickup Truck is for now, the EV startup already scored a significant contract, at least symbolically. NASA selected Canoo to transport astronauts to the upcoming Artemis spaceships for missions to the moon in 2025.

With a bit of luck, the Canoo truck just might be available to reservation holders in 2023. Learn more about Canoo here.

The State of Texas is alleging in a new lawsuit that online car retailer Vroom has routinely failed to disclose vehicle history, vehicle features, and work done on vehicles it sold to customers in Texas. On April 20, Texas Attorney General Ken Paxton filed a lawsuit in the District Court of Travis County against Vroom, which also operates as Texas Direct Auto.

An unrelated class-action lawsuit has already been filed against the online retailer, and Florida has filed a complaint regarding Vroom’s title transfer issues in the state. Consumer advocacy groups have repeatedly issued warnings following the multitude of complaints received about Vroom.

The lawsuit notes that since 2020, consumers have filed nearly 5,000 complaints with the Better

Business Bureau and Office of the Attorney General of Texas. The vast majority of complaints have been filed over the past year. The lawsuit states that Vroom has “not managed their growth effectively and have allowed inadequate systems and procedures to spiral into violations of the DTPA [Texas Deceptive Trade Practices Consumer protection Act].”

Specifically, the lawsuit alleges the following violations:

The State of Texas’ lawsuit details a few examples of the poor conditions of vehicles misleadingly sold to Texas customers.

“In one case, within hours of delivery, a Texas consumer reportedly noticed that the oil change and engine service lights came on, and there was an irregularity in the windshield and scratches on the wheel. The consumer took the vehicle to a nearby dealership, and after an inspection was told it needed spark plugs, new filters, an oil change, and a radiator leak to be repaired.”

“In another case, a Texas consumer complained that when Defendants delivered the vehicle, the consumer immediately noticed a strong odor in the interior that she described as similar to being near a boat. She noted that the interior carpet looked as if it had been completely replaced. The next day, she took it to a mechanic for a standard inspection. The inspection identified several areas of internal rust that could only be caused by sitting in water for an extended amount of time, as well as other conditions that indicated flood damage.”

Yet another example quoted a Vroom customer whose ‘new’ car needed $8,000 in repairs soon after buying from the online retailer. In a sad but almost comical case, a customer bought a car from Vroom with a driver’s seat that was pushed as far back as it could go without the ability to move it forward. So much for the “rigorous inspection process” that Vroom claims to abide by.

The Texas lawsuit against Vroom also details numerous examples of title and registration delays stretching far beyond the 60-day window permitted for registering a new vehicle.

In 2021, Vroom reported well over $2.4 billion in revenues. profits rose 171% year-over-year to $164.7 million. With a class action lawsuit already filed and the States of both Florida and Texas hot on their tails, Vroom’s honeymoon with the American consumer may be coming to an abrupt end. We’ll keep you up to date with the latest at caredge.kinsta.cloud.

Have you experienced something similar at Vroom or any other car retailer, including a traditional dealership? Leave a review of your car buying experience to help others avoid headaches. Had an amazing experience? Your review can help car buyers give their business to honest dealers who deserve it. You can also simply view the results to see what others are experiencing near you!

If you think you’ve been the victim of deceptive dealer practices, you can find contact info for every state’s attorney general and consumer protection office here.